Description

<iframe width="560" height="315" src="https://www.youtube.com/embed/MLQJwfFdWVA" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

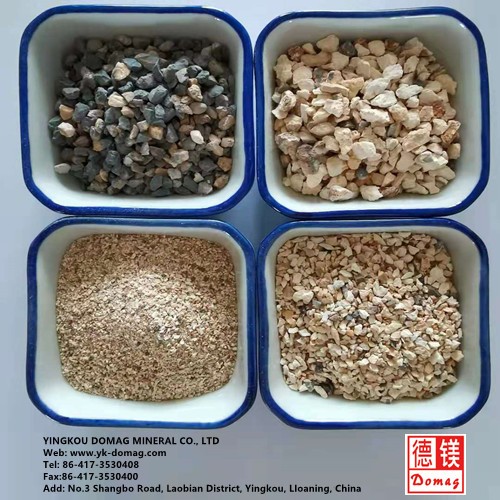

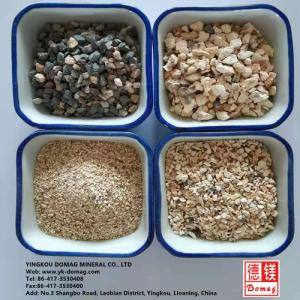

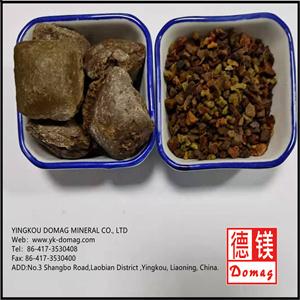

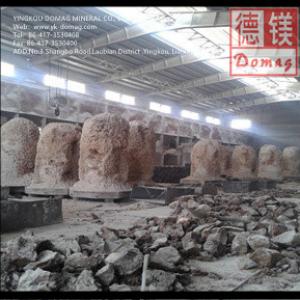

1. Bauxite clinker is made from bauxite by high temperature calcinating.

2. Bauxite are calcinated in shaft kiln, down-draft kiln and rotary kiln, calcination temperature is about 1450-1600°C.

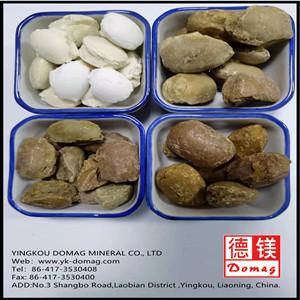

3.Bauxite Al2O3 is more than 50%,The main mineral composition is mullite and corundum and trace the cristobalite, etc.

4.Its thermal stability, high mechanical strength and resistance to molten slags make Calcined Bauxite an ideal raw material in the production of shaped and unshaped refractories for the steel industry, foundries, glass and cement plants.

5. Size available: 0-1/1-3/3-6/6-10mm, 200 /250 /270/325 mesh, or under customer’s requirement.

Bauxite

Type

CHEMICAL CONTENT, %

Bulk density

g/cm3

Al2O3

≥

Fe2O3

≤

TiO2

≤

K2O+Na2O

≤

CaO+MgO

≤

DM - BX50-60

50-60

3.0

4.0

0.3

0.5

2.45

DM - BX60-70

60-70

3.0

4.0

0.3

0.5

2.65

DM - BX75

75

3.0

4.0

0.3

0.5

2.70

DM - BX80

80

3.0

4.0

0.3

0.5

2.80

DM - BX85

85

2

4.0

0.3

0.5

3.00

DM - BX86

86

2

4.0

0.3

0.5

3.10

DM - BX87

87

2

4.0

0.3

0.5

3.20

DM - BX88

88

1.8

4.0

0.25

0.5

3.25

DM - BX90

90

1.8

4.0

0.25

0.5

3.30